Waste tyre pollution is now increasingly heavier as the number of waste tyres produced increases. As a result, finding a solution to discard waste tyres and stop or reduce pollution produced by waste tyres is critical for that planet. Luckily, the waste tyre pyrolysis plant is playing a progressively important role from the face of your urgent tyre scrapping problem. Additionally, it can be becoming more and more alluring to investors.

Waste tyre recycling is actually a serious problem due to its large weight, volume, and assortment of materials. Having said that, the waste tyre pyrolysis plant emerges at the historic moment according to these features. Its implementation not just solves the environmental and safety issues that have arisen because of its vast buildup but also generates economic benefits and helps to create new economic clout.

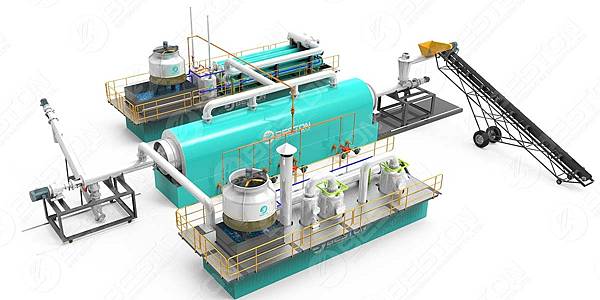

Just how a Tyre Pyrolysis Plant Works

Waste tyre pyrolysis is the process of deteriorating the main chain of rubber in tyres with adequate heating. Fuel oil, uncondensable gas, coal tar, and insulated wire would be the major end products. Because of the various pyrolysis techniques, each product carries a unique composition.

It can be possible to recycle waste tyres into sustainable energy utilizing the tyre pyrolysis process, without causing secondary pollution on the environment. Besides, the new kind of waste tyre pyrolysis facilities is all designed with smoke cleaning systems, bad odor elimination systems, and water circulation systems. This helps to ensure that neither the environment nor water is polluted.

Seven Steps of your Pyrolysis Process

1. To get ready for shredding the tyres, use the wire drawing equipment to remove the tyre wire

2. To purchase small bits of tyres, shred tyres without strong steel wire inside a tyre shredder shredded tyres are simpler to pyrolyze.

3. Send the shredded tyres on the pyrolysis reactor by way of a closed continuous feeder as well as heat it with fuel. This stage provides for automatic feeding, which lowers labor costs and increases investment.

4. Oil gas is produced as soon as the reactor is heated to your given temperature the oil gas then passes through a three-step cooling system, including a vertical condenser, a horizontal condenser, as well as a cooling tower, to be cooled down to have oil, which is then stored in oil tanks.

5. After receiving treatment by a tail gas cleaning and odor removal system, the cooling tower's non-condensable gas are able to be recycled to heat the reactor.

6. During the combustion of fuel, smoke is going to be produced, which may be ejected after being treated by the smoke cleaning system.

7. Finally, the carbon screw conveyor can collect the carbon black within the pyrolysis reactor.

Find Yourself

Waste Tyre Pyrolysis plants are a form of environmentally friendly machine employed to discard waste tyres. Pyrolysis oil, carbon black, and steel wire can be obtained by pyrolyzing discarded tyres. Currently, enormous quantities of scrap tyres must be handled immediately. As such, it is becoming more and more vital to deal with the situation of waste tyre stacking within an environmentally responsible and lucrative manner. Because of this, an increasing number of people choose to put in a tyre pyrolysis plant.

留言列表

留言列表 Beston Company

Beston Company