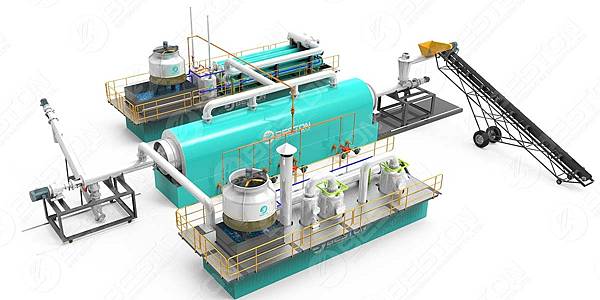

A tyre pyrolysis plant uses an industrial method that converts used tyres into liquid fuel, like oils and gases. There are 2 types of processes utilized: direct and indirect. Within a direct process, the rubber is heated in an oxygen-free environment at 300 to 600 °C for many hours, resulting in the hydrocarbon chains throughout the tyre to break down into smaller pieces. A byproduct with this reaction is carbon black, that may be further refined and blended with diesel or gasoline, depending on the type of machine you need to run using it (you might run your car onto it too!). An indirect process involves heating tyres until they produce coke (an increased-grade carbon). Then coke is heated further to make the fuel.

Both in cases, oil and gas will be the main products of pyrolysis. Oil through the pyrolysis process can be refined into various highly desirable petroleum products, such as aviation turbine fuel (ATF), organic solvents, and base oils. The gas byproduct from your tyre pyrolysis plant may also be used as a substitute for gas in furnaces or boilers that require high temperatures for industrial processes including glass melting or smelting metal ores.

One of the leading great things about using tyre derived fuel as an alternative to traditional non-renewable fuels is the fact there is absolutely no shortage of a supply source. There are about 100 million tonnes of used tyres generated per year worldwide. In addition, an additional advantage may be the lowering of carbon dioxide released to the atmosphere in comparison to using traditional fuels like petrol or diesel because no new fossil fuel is essential.

A tyre pyrolysis plant can be used as the incineration of not only waste tyres, and also every other rubber products (slippers, inner tubes, bathing caps). They are also converted into fuels like gasoline or diesel.

Tyres are a great source of hydrocarbons since they contain over 70% carbon by weight. Additionally, tyres contain as much as 50% water which significantly reduces overall energy production capacity.

However, there are actually three major issues concerning tyre pyrolysis: separation of liquids from solids in the tyres, removing of steel wire in the pyrolysis oil product, and generating heat within a tyre pyrolysis plant to reach high enough temperatures.

Still, despite having those challenges to conquer, tyre pyrolysis remains an infinitely more viable way to handle used tyres than landfill or incineration. The tyre pyrolysis technology converts waste tires into multiple valuable items like fuel oil, pet coke, carbon black, etc. It gives you an alternate for landfills, which only accept lightweight materials for example paper or plastic wastes. With landfills, also, there is absolutely no prospect of producing more energy. Additionally it is a preferable replacement for incineration, which puts harmful byproducts in the atmosphere.

To summarize, though tyre pyrolysis has its unique challenges to get over, those are worthwhile if you examine the environmental benefits that happen to be gained due to transforming the used tyres into valuable products like gas and oil, as opposed to merely burying them or burning them.

留言列表

留言列表 Beston Company

Beston Company